Ordering and producing a customized IC (Integrated Circuit) fixture for personal test requirements involves several detailed steps to ensure you get a functional and reliable product:

- Define Your Test Requirements: Clearly outline what you need the IC fixture for. Consider factors such as:

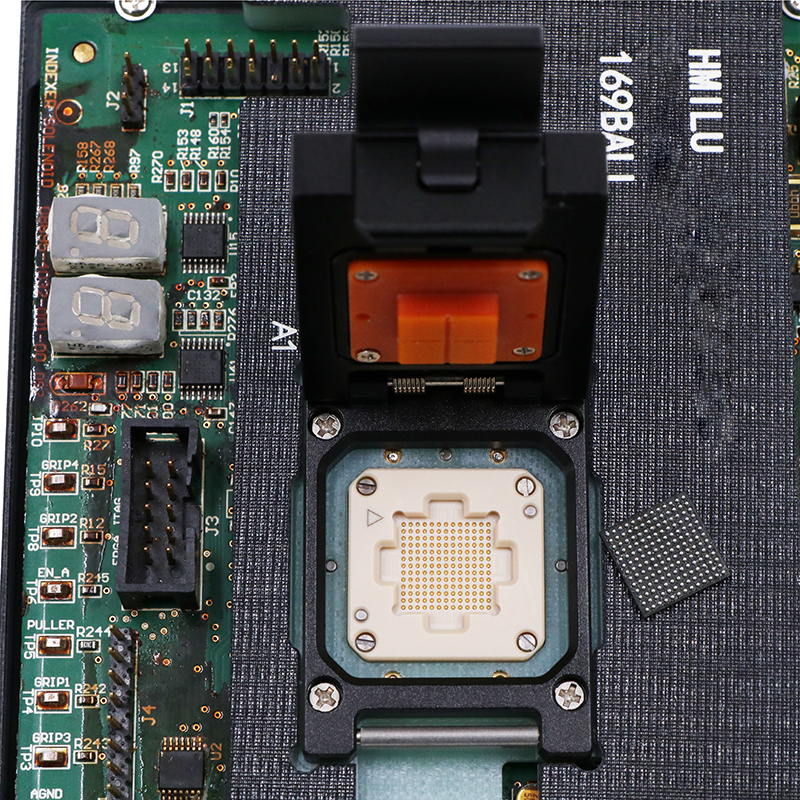

- Types of ICs to be tested (e.g., package types, pin configurations from IC datasheet file or POD picture)

- Test environment (e.g., temperature requirements, signal integrity considerations, high speed signal, frequency or bandwidth and so on)

- Interface requirements (e.g., connection to testing equipment, test points)

- can provide this test PCBA board and Sample IC to supplier

- optional: test PCBA board Gerber file

- other requirements: cooling way and so on

- Research Suppliers or Manufacturers: Look for suppliers or manufacturers who specialize in producing custom IC fixtures or test sockets. This can include searching online, checking industry directories, or seeking recommendations from colleagues in your industry.

- Contact Potential Suppliers: Reach out to the suppliers with your detailed requirements. Provide specifications such as:

- Types of IC packages (e.g., QFN, SOP, BGA)

- Pin configuration and pitch

- Material requirements (e.g., for thermal conductivity, durability)

- Electrical specifications (e.g., temperature requirements, signal integrity considerations, high speed signal, frequency or bandwidth,voltage, current and so on)

- Mechanical specifications (dimensions, tolerances)

- Provide test board picture to show which IC need to be customized test fixture, where positioning hole can be mounting this IC socket,which interface need to install or expand on fixture cover and other request.

- how many IC test fixture you need

- other special requirements

- Request Quotations: Obtain quotations from multiple suppliers. Compare pricing, lead times, and their ability to meet your specifications. Ensure the supplier is capable of handling the volume you require.

- Review Design and Prototyping: Some suppliers may offer design services and prototypes. Review their design proposals and, if possible, request a prototype or sample to test compatibility with your ICs and testing equipment.

- Finalize Specifications and Place Order: Once satisfied with a supplier, finalize the specifications, including pricing, delivery terms, and any additional requirements. Place your order accordingly.

- Production and Quality Control: The supplier will manufacture the IC fixtures according to your specifications. Monitor the production process if necessary to ensure quality control measures are followed.

- Testing and Validation: Upon receiving the IC fixtures, conduct thorough testing and validation. Ensure they meet your requirements for functionality, reliability, and compatibility with your testing setup.

- Feedback and Adjustments (if needed): Provide feedback to the supplier based on your testing results. If adjustments are necessary, communicate these promptly to ensure corrections are made.

- Documentation and Support: Obtain proper documentation from the supplier, including specifications, drawings, and any warranty information. Maintain a good relationship for ongoing support and future orders.

By following these steps, you can effectively order and produce a customized IC fixture tailored to your personal test requirements, ensuring it meets your testing needs accurately and reliably.

发表回复