I. Overview of Optical Module Chips

Optical module chips are core components in optical communication systems, playing a critical role. They are primarily used to convert electrical signals into optical signals and vice versa, enabling high-speed data transmission. Optical module chips are widely used in data centers, communication networks, fiber optic transmission, and other areas. The core functions of optical module chips include transmitters and receivers: transmitters convert electrical signals into optical signals, while receivers convert optical signals back into electrical signals.

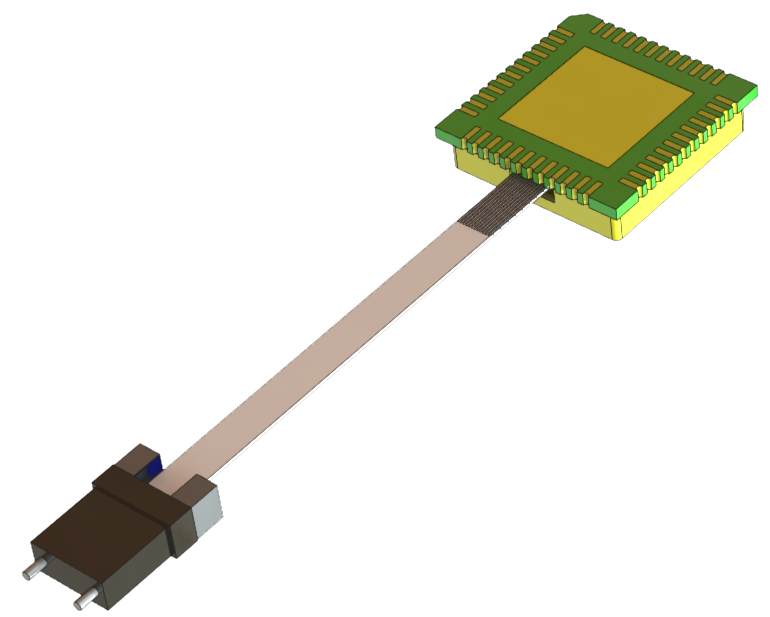

Optical module chips come in various packaging forms, with LCC (Leadless Chip Carrier) being a common one. LCC packaging offers good thermal and electrical performance, suitable for high-speed signal transmission and high-frequency applications. Now, standard packages: LCC20、LCC32、LCC40、LCC48 and so on.

II. Performance of Optical Module Chips

The performance of optical module chips is a key factor in evaluating their effectiveness in optical communication systems. The main performance indicators include:

- Transmission Rate: The transmission rate of an optical module chip is a core performance indicator. It determines the bandwidth and speed of data transmission. Common rates include 1G (Gigabit), 10G, 25G, 40G, and 100G. Higher rates imply stronger data transmission capabilities, requiring more advanced technology and design precision.

- Wavelength: The operating wavelength of an optical module chip significantly impacts its application. Common wavelengths include 850nm, 1310nm, and 1550nm. Different wavelengths are suited for different transmission distances. For instance, 850nm is suitable for short-distance transmission, such as within data centers, while 1550nm is ideal for long-distance transmission, such as metropolitan or wide-area networks.

- Power Consumption: The power consumption of an optical module chip is an important measure of its energy efficiency. Lower power consumption helps reduce overall system energy use and cooling requirements. Power optimization is crucial for large data centers and high-performance computing systems.

- Transmission Distance: The transmission distance of an optical module chip depends on the wavelength, fiber type, and power output. Different types of optical module chips are designed for various transmission distances, ranging from a few meters to hundreds of kilometers. Short-distance modules are typically used for internal connections, while long-distance modules are used for extended transmission.

- Signal Integrity: Signal integrity is a critical performance indicator in data transmission, including low error rates and high signal quality. Ensuring signal integrity is vital for system stability and accurate data transmission.

- Operating Temperature Range: The operating temperature range of optical module chips should suit different environmental conditions. Common ranges include commercial grade (0°C to 70°C) and industrial grade (-40°C to 85°C). Different temperature ranges are suited for various application scenarios. For instance, industrial-grade chips can operate stably in extreme environmental conditions.

III. Purpose of Optical Module Chip Test Sockets

Optical module chip test sockets are specialized devices used for performance verification and quality control of optical module chips. The main purposes include:

- Performance Testing: Test sockets evaluate various performance indicators of optical module chips, such as transmission rate, wavelength, and power consumption. Performance testing ensures that the chips meet design specifications and application requirements, forming the basis for stable operation in real-world applications.

- Compatibility Verification: Test sockets verify the compatibility of optical module chips with different devices, including switches, routers, and fibers. Compatibility verification ensures that the chips integrate seamlessly with various network devices, enhancing system flexibility and compatibility.

- Fault Diagnosis: When faults occur with optical module chips, test sockets help diagnose issues and identify fault causes. For example, test sockets can detect optical signal attenuation, data transmission errors, and provide repair recommendations. This helps quickly resolve problems and minimize system downtime.

- Quality Control: During the production of optical module chips, test sockets are used for quality inspection. They ensure that all outgoing chips meet quality standards, improving product consistency and reliability. Quality control is crucial for ensuring stable performance in real-world applications.

- R&D Support: In the development of optical module chips, test sockets provide a vital validation platform for engineers. Engineers can use test sockets to assess new designs’ performance and reliability, identify and address potential design issues, accelerating development and enhancing market competitiveness.

IV. Compatibility Testing of Optical Module Chip Test Sockets

Compatibility testing of optical module chip test sockets includes the following:

- Standard Testing: Standard testing evaluates the basic performance indicators of optical module chips, such as transmission rate, wavelength, and power consumption. These tests ensure that the chips perform according to specifications under common conditions. Standard testing is foundational for validating optical module chips.

- Extreme Testing: Extreme testing assesses optical module chips under high temperatures, low temperatures, high humidity, and other extreme environmental conditions. These tests validate the chips’ stability and reliability in harsh environments, ensuring they function properly in special application scenarios.

- Compatibility Testing: Compatibility testing verifies optical module chips’ compatibility with various devices and systems. This includes integration with different brands and models of switches, routers, and fibers. Compatibility testing ensures that the chips can seamlessly integrate into different network devices, improving system flexibility.

- Signal Integrity Testing: Signal integrity testing evaluates the integrity of signals during data transmission. This includes metrics such as error rates and signal attenuation. Signal integrity testing ensures stable and accurate data transmission, minimizing data loss and errors.

- Long-Term Stability Testing: Long-term stability testing involves prolonged operation of optical module chips to observe performance changes and stability over time. This testing reveals potential issues, such as performance degradation or increased failure rates, during extended use.

- Aging Testing: Aging testing simulates long-term usage conditions to assess the reliability of optical module chips. Accelerated aging processes, including high-temperature and high-humidity tests, help identify potential defects and reliability issues over time, providing a basis for long-term stable operation.

V. Conclusion

Optical module chips play a crucial role in optical communication systems, directly impacting data transmission efficiency and stability. Optical module chip test sockets, as specialized devices for performance verification and quality control, are essential for ensuring the reliability and efficiency of optical module chips in real-world applications. Comprehensive testing, including standard, extreme, compatibility, signal integrity, long-term stability, and aging tests, ensures that optical module chips perform reliably under various conditions.

发表回复