Driven by the Chip Testing Market

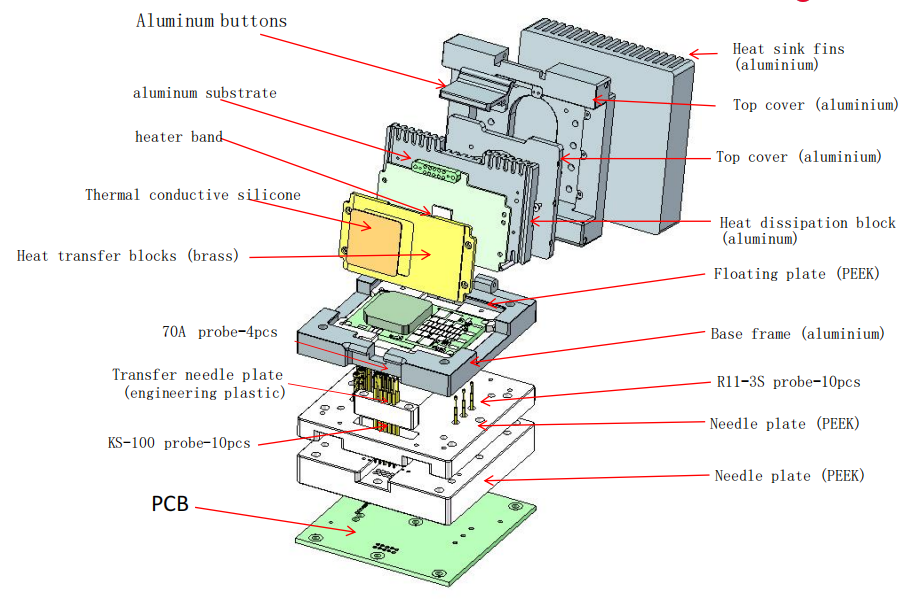

The popularization of smart electronic devices has led to rapid development in the chip testing market. IC sockets, including ANDK customized IC sockets, play a crucial role in this process. Chips need strict testing before leaving the factory. Some chips require a high-temperature testing environment due to their applications or heat generation during operation. Self-heating test sockets can meet this demand. With the development of technologies such as 5G and the Internet of Things, the demand for chip testing is increasing, which drives the growth of the market demand for self-heating test sockets and related IC sockets like ANDK customized ones.

Improving Testing Efficiency

Traditional high-temperature testing methods have problems such as inconvenience in observation, easy aging of PCB boards in high-temperature environments, slow heating, and difficult operation. Self-heating test sockets come with heating components and can conduct direct high-temperature testing on the tested chips on a regular workbench. This eliminates the need to put the entire test platform into a high-temperature oven, effectively ensuring the lifespan and stability of the test scheme board. ANDK customized IC sockets, with their unique design and features, can also contribute to more efficient testing processes. It also allows for continuous replacement of test chips and observation of the testing process, greatly improving testing efficiency and accuracy.

Meeting Diverse Requirements

Different chips and electronic devices have different requirements for the testing environment. Self-heating test sockets can precisely control the temperature and simulate different high-temperature environments. For example, in the automotive electronics field, they can be used for the stability testing of vehicle-mounted components under extreme temperature conditions to ensure their reliability in actual use. ANDK customized IC sockets can be tailored to meet the specific needs of various applications, further enhancing the adaptability of the testing solutions.

Application Scenarios of Self-Heating Test Sockets

Semiconductor Chip Testing

- Engineering Verification Testing (EVT): In the early stage of product development, it is necessary to comprehensively evaluate the performance of chips. Self-heating test sockets can simulate the high-temperature environment in which chips actually operate, conduct high-temperature performance testing on early samples, and ensure that the functions and parameters of chips meet the design requirements under high-temperature conditions. ANDK customized IC sockets can be used to provide more accurate and reliable testing for specific semiconductor chips.

- Production Testing: During the mass production of chips, large-scale testing is required to screen out unqualified products. Self-heating test sockets can quickly and accurately conduct high-temperature testing on chips, improving production efficiency and product quality. The use of ANDK customized IC sockets can optimize the production testing process and ensure the consistency of chip quality.

- Quality Assurance (QA): Before products leave the factory, self-heating test sockets can conduct high-temperature reliability testing on chips to ensure that each chip leaving the factory can meet customer requirements under high-temperature conditions and guarantee the quality of the final products. ANDK customized IC sockets can be an important part of the quality assurance system, providing customized testing solutions.

- Failure Analysis (FA): When a chip fails, self-heating test sockets can test the chip under high-temperature conditions, accurately and stably locate the chip failure point, and help engineers quickly find and solve the problem. ANDK customized IC sockets can be designed to better support failure analysis, enabling more in-depth and accurate investigations.

Electronic Device Testing

- Smartphones: To test the battery life and screen display effect of smartphones in extreme climates, self-heating test sockets can be used to simulate different temperature environments to ensure the stable performance of smartphones under high-temperature conditions. ANDK customized IC sockets can be applied to meet the specific testing needs of smartphone chips, ensuring the quality and performance of these devices.

- Automotive Electronics: The automotive electronics field has extremely high requirements for the reliability of electronic devices. Self-heating test sockets can be used to verify the working stability of vehicle-mounted computers, sensors, battery packs, motor controllers and other components under high-temperature conditions, ensuring the safe operation of vehicles in high-temperature environments. ANDK customized IC sockets can be designed to withstand the harsh automotive environment and provide reliable testing for automotive electronic components.

Other Fields

- Aerospace: Aerospace equipment needs to operate in extreme temperature environments. Self-heating test sockets can simulate high-temperature environments at high altitudes and conduct high-temperature testing on aerospace electronic equipment to ensure its reliability and stability in complex environments. ANDK customized IC sockets can be developed to meet the high – precision and high – reliability requirements of aerospace applications.

- New Energy Industry: In the new energy industry, the electronic components of equipment such as solar panels and wind turbines also need performance testing under high-temperature conditions. Self-heating test sockets can meet these testing requirements and ensure the quality and performance of new energy equipment. ANDK customized IC sockets can be tailored to the unique characteristics of new energy electronic components, providing more effective testing solutions.

发表回复