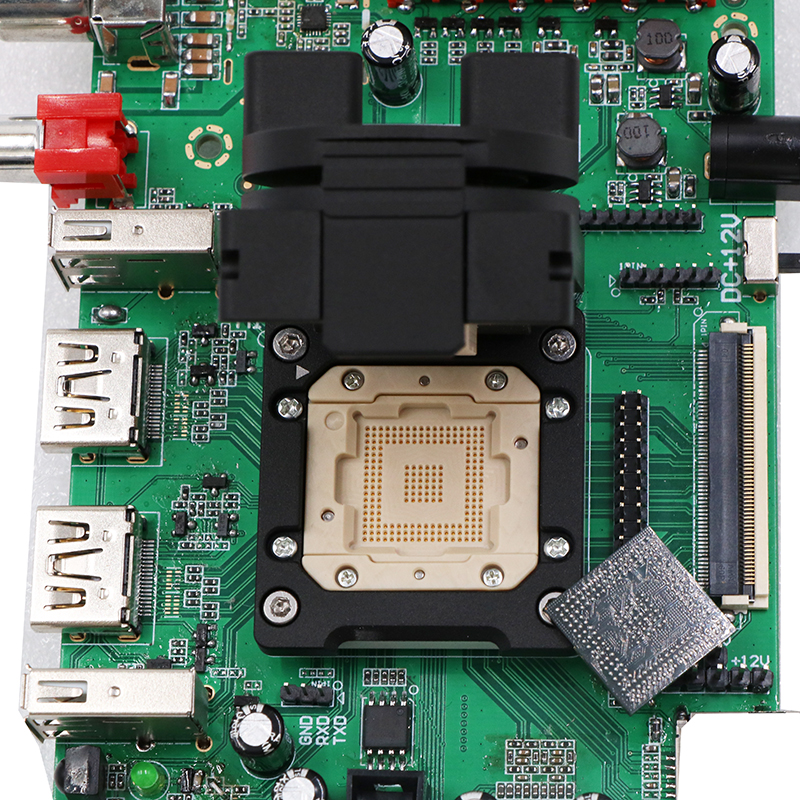

A chip test fixture is a device used for testing integrated circuits (ICs) or other electronic components. It is primarily used during production to perform functional testing, performance verification, and troubleshooting.

Uses:

- Functional Testing: To verify whether the chip operates according to design specifications.

- Performance Evaluation: To test the chip’s performance under various conditions, such as speed and power consumption.

- Troubleshooting: To help identify and locate defects or failures within the chip.

- Production Efficiency: To enhance the automation of product testing, reducing human error in testing processes.

General Structure:

- Fixture Part: Used to secure and connect the chip being tested, ensuring good contact.

- Test Interface: Includes various interfaces (such as pins and sockets) to connect the chip with testing equipment.

- Signal Generator: Generates test signals to simulate actual operating conditions.

- Measuring Equipment: Records test results, typically including oscilloscopes, multimeters, etc.

- Control System: Controls the testing process through software, collects data, and analyzes results.

Implementation:

The design of a chip test fixture usually needs to be customized based on the specific chip type and testing requirements. Common implementation methods include:

- Hardware Design: Using PCB design for interfaces and connectors.

- Mechanical Structure: Constructing fixtures from suitable materials to ensure stability and reliability.

- Software Programming: Writing test programs to automate the testing process and improve efficiency.

Through this structure and functionality, chip test fixtures play a crucial role in the electronics manufacturing industry.

发表回复