In today’s era of rapid digital development, the performance and reliability of memory chips are of crucial importance to the operation of various electronic devices. LPDDR4 (Low Power Double Data Rate 4), as a double – data – rate memory chip with low – power and high – performance characteristics, is widely used in many fields such as mobile devices like smartphones, tablets, laptops, and servers. To ensure the quality and stability of LPDDR4 chips, comprehensive testing is essential, and the LPDDR4 test socket plays a key role in this process. Now, let’s take a detailed look at the relevant content surrounding the LPDDR4 test socket.

1. Basic Information of the Tested Chip

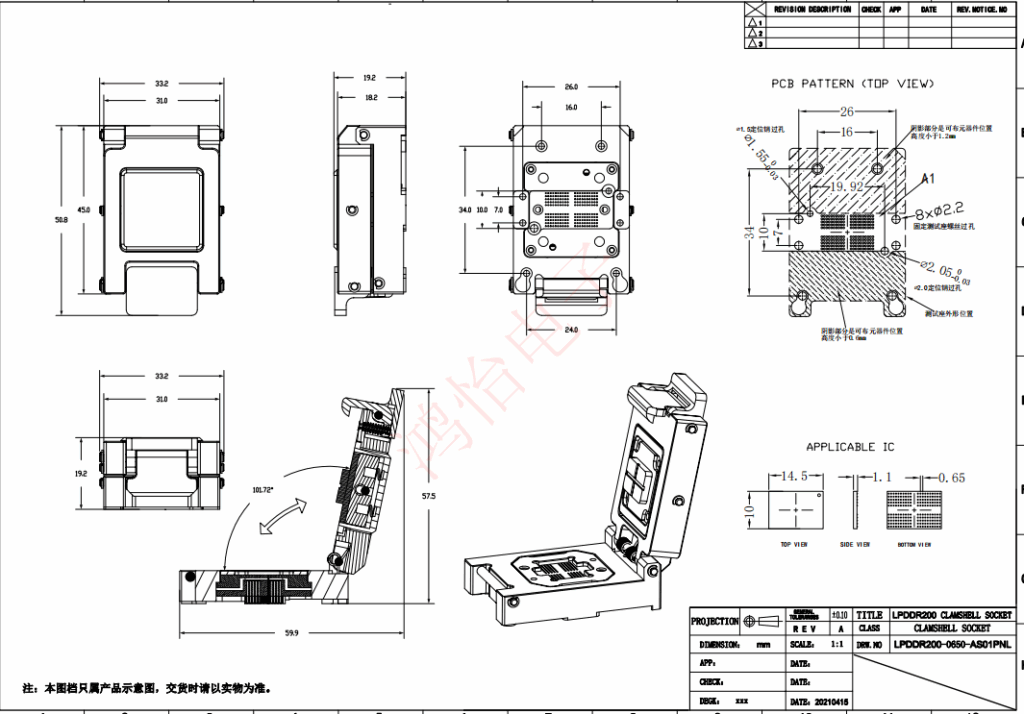

The tested LPDDR4 chip has specific dimensional specifications. It is 14.5mm in length, 10mm in width, and 1.1mm in thickness, with a pin center – to – center spacing of 0.65mm. These precise dimensional parameters determine that the test socket must be highly compatible with the chip to ensure accurate connection of the chip pins, stable electrical connection, and reliable testing.

2. Chip Function Testing Process and Significance

The function testing of LPDDR4 chips is a comprehensive and meticulous process aimed at verifying whether the performance and functions of the chips under various working conditions meet the design requirements. Function testing covers multiple aspects, including but not limited to data read – write operations, clock synchronization, power management, error detection and correction, etc.

Data read – write operation testing is one of the core points of function testing. By writing different types of data to the chip and then performing read operations, the test socket can verify whether the chip can accurately store and read data. Clock synchronization testing ensures that the chip can maintain precise synchronization with the external clock signal to ensure the stability of data transmission. Power management testing is used to evaluate the power consumption of the chip under different working modes, ensuring that it can achieve low – power operation while meeting performance requirements. Error detection and correction testing can detect whether errors occur during data transmission and verify whether the built – in error correction mechanism of the chip can effectively correct these errors.

Through these function tests, potential defects and problems in the chip, such as data transmission errors, clock jitter, and abnormal power consumption, can be detected in a timely manner. This not only helps to improve the yield rate of the chips but also ensures the stability and reliability of the final products in actual use.

3. Requirements for the Test Socket

The requirements for the LPDDR4 test socket are also very strict, mainly including the following aspects:

- Good Contact: The test socket needs to achieve good contact with the pins of the LPDDR4 chip, and the contact yield should reach a very high standard to ensure the stability and accuracy of signal transmission during the testing process. Any poor contact may lead to inaccurate test results and misjudgment of the chip’s performance.

- High – Precision Adaptation: Due to the small pin center – to – center spacing of the LPDDR4 chip, the test socket must have a high – precision manufacturing process to ensure accurate alignment with the chip pins and achieve a tight connection. Even a slight deviation may affect the test results.

- Low Interference: During the testing process, the test socket needs to minimize interference with the chip signals to ensure that the test results can truly reflect the performance of the chip. This requires the test socket to adopt a design with low noise, low parasitic capacitance, and inductance.

- Long Service Life: The test socket needs to have a long service life and be able to withstand multiple insertions, extractions, and tests. Frequent replacement of the test socket will increase the testing cost and time and reduce the testing efficiency.

- Easy Maintenance: Convenient maintenance is also an important requirement for the test socket. When the test socket fails, it can be quickly repaired and replaced, reducing the interruption time of the testing and improving the testing efficiency.

4. Our Solution

Our LPDDR4 test socket is a product that has been carefully designed and optimized, with the following characteristics:

- Precise Dimensional Adaptation: The test socket is strictly designed and manufactured according to the dimensional specifications of the LPDDR4 chip, with extremely high dimensional accuracy, ensuring perfect compatibility with the chip and achieving stable electrical connection and reliable testing.

- High – Quality Materials and Processes: High – quality materials and advanced manufacturing processes are used to ensure that the test socket has good mechanical and electrical properties. For example, the pins are made of highly conductive metal materials to effectively reduce the contact resistance and improve the quality of signal transmission.

- Anti – Interference Design: In the design of the test socket, anti – interference factors are fully considered, and a shielding structure and a low – noise circuit design are adopted to effectively reduce the impact of external interference on the test results.

- Convenient Plug – and – Play Design: The test socket adopts a user – friendly plug – and – play design, which facilitates the installation and removal of the chip and reduces damage to the chip and the test socket during the operation. At the same time, the force during the plug – and – play process is moderate, ensuring a tight contact between the pins and the test socket.

- High Maintainability: The structure of the test socket is designed to facilitate disassembly and maintenance. When a failure occurs, the damaged parts can be quickly replaced, reducing the maintenance cost and time. In addition, the test socket is equipped with corresponding detection interfaces to facilitate fault diagnosis and performance testing.

发表回复